Torque Settings Imperial Bolts Allfast Solutions Free Download Nude Photo Gallery

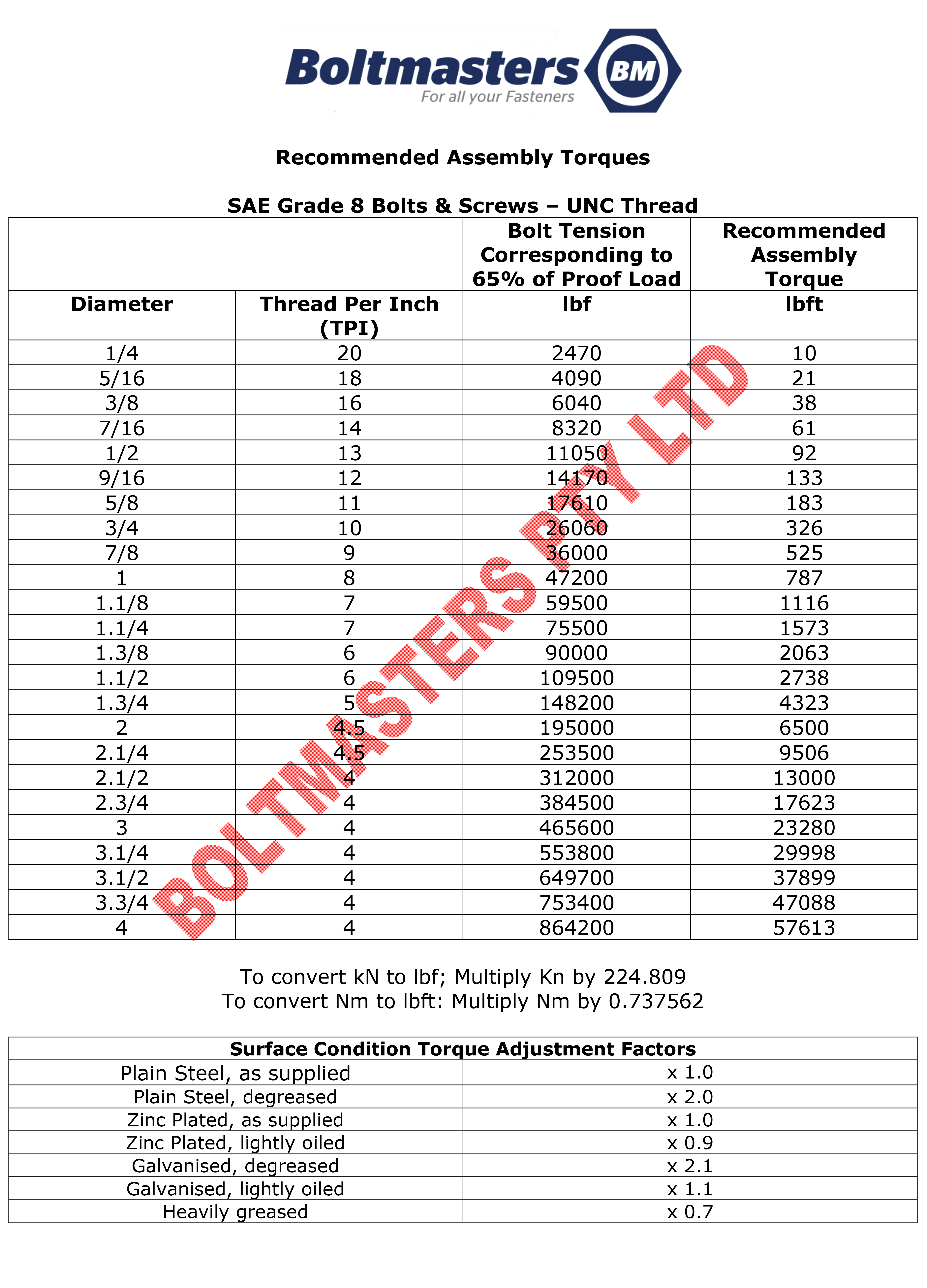

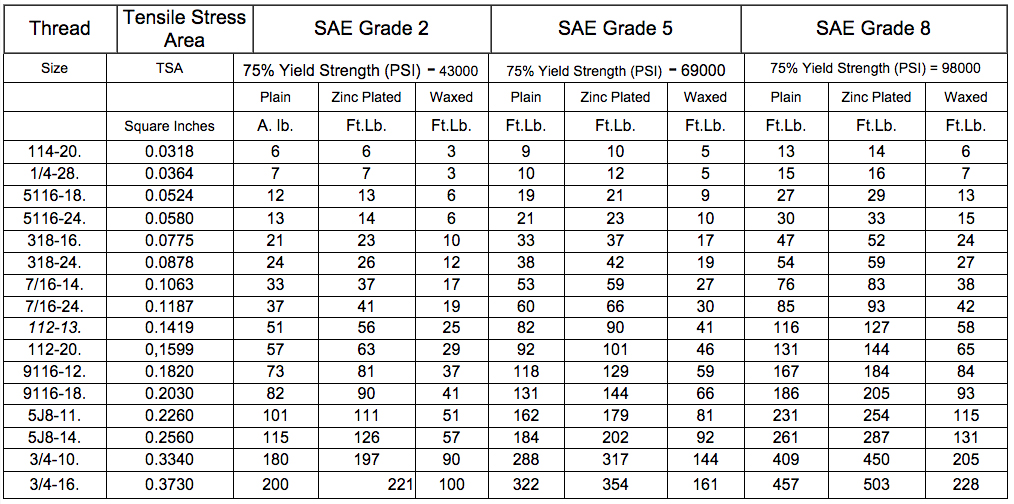

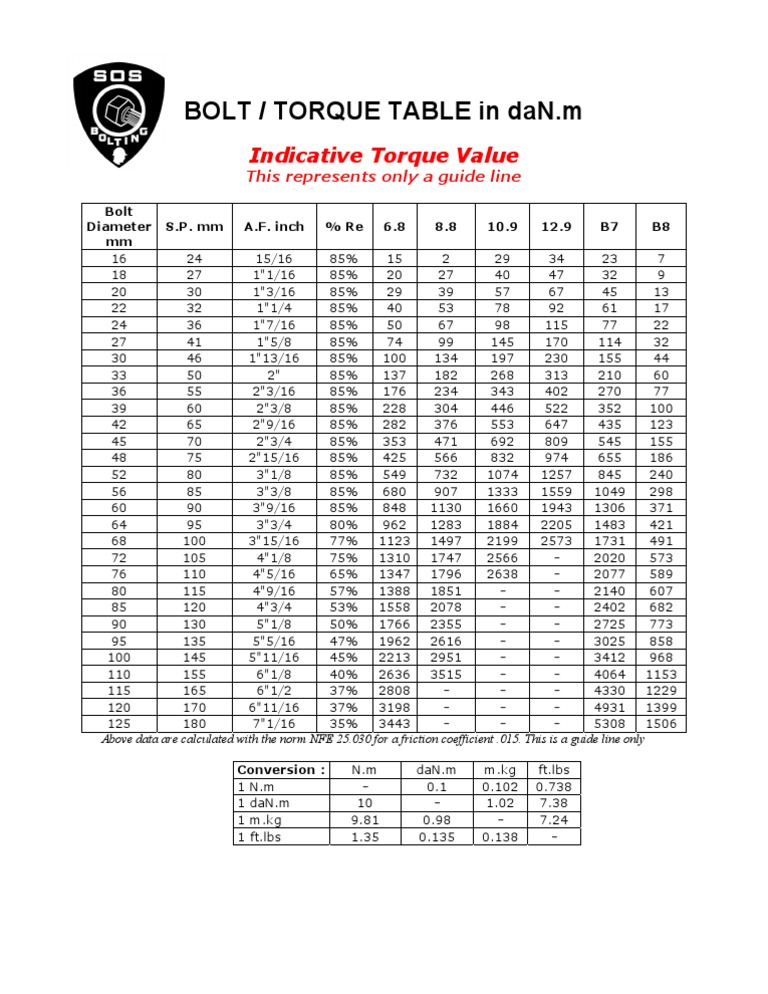

8: 7: 3 ⁄ 8: 16: 2,567: 1,925: 6: 15. = .10, hot dip galvanized = .25, and plain non-plated bolts (as received) = .20. Torque has been converted into ft/lbs by dividing the result of the formula by 12; All calculations are for Coarse Thread Series (UNC). Grade 2 calculations only cover fasteners.

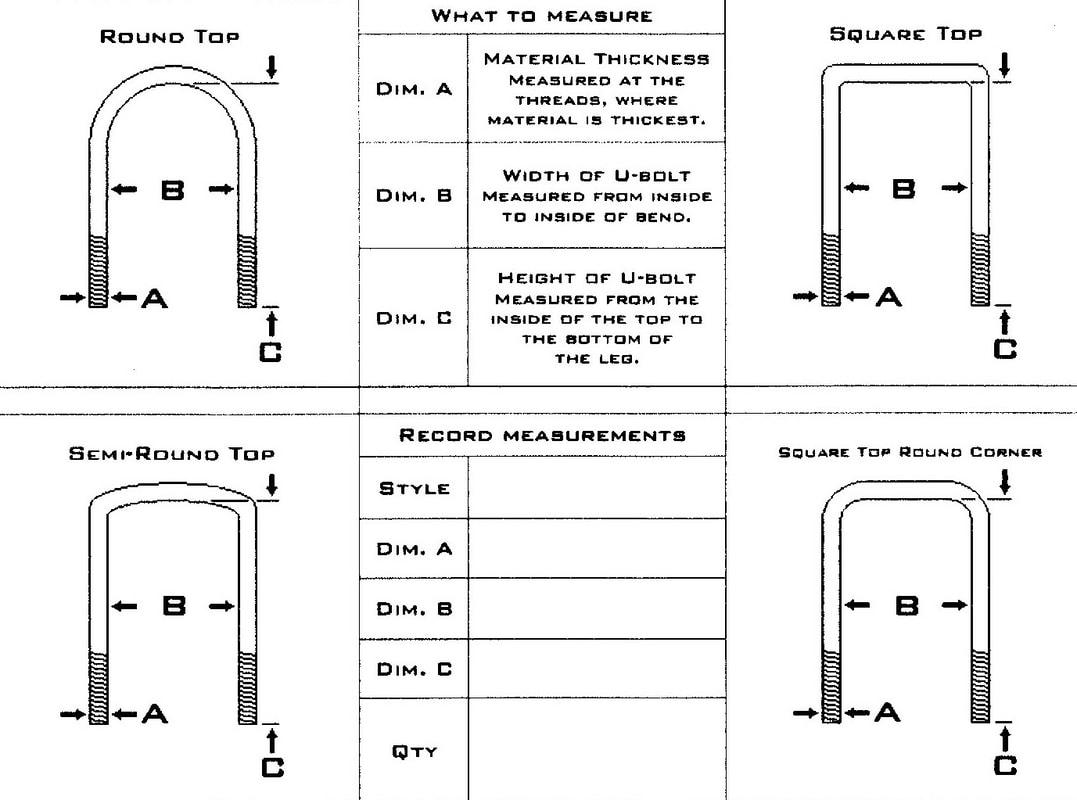

Ubolt Kit, SemiRound 7/8" x 13" x 31/2" Wide

Because there are many variables that affect the torque-tension relationship, the only way to determine the correct torque is through experimentation under actual joint and assembly conditions. Bolt torque chart reference guides include Grade 2, B7, A307, A325, Grade 8, A490, and Grade 5. AFT Fasteners is your trusted source for fastener.

u Bolt Torque Chart Manufactured Goods Mechanical Engineering

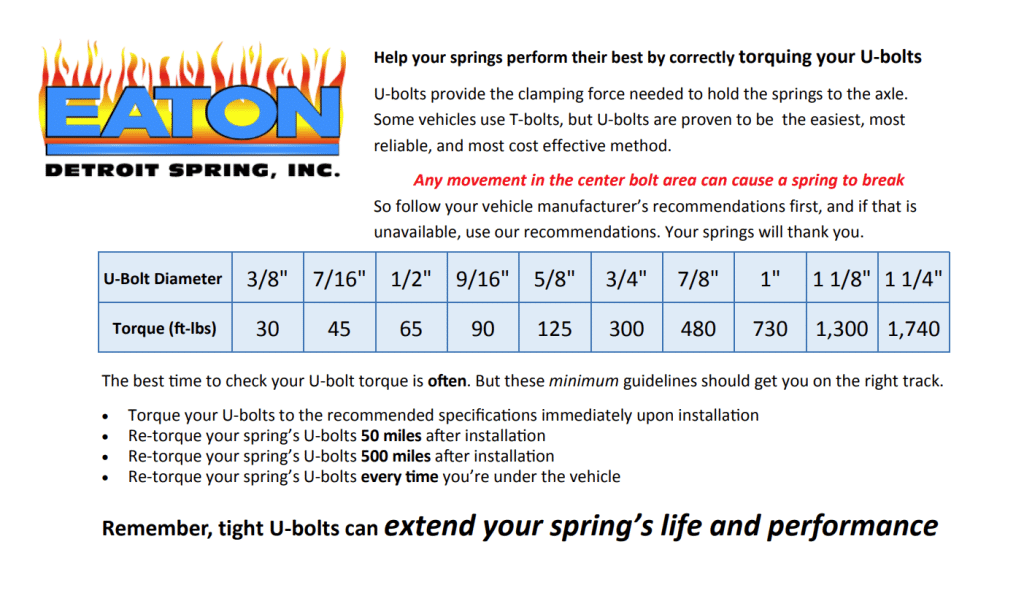

U-Bolt Torque Recommendations. Here are our recommendations for u-bolt torque. U-Bolt Torque Recommendations . Thread Size & Nut Hex Size:. 120-130: 5/8 (15/16 Hex) 170-180: 3/4 (1-1/16 Hex) 275-300 . U-Bolts should be well lubricated with an anti-seize compound; Tighten and torque U-Bolts in a cross-pattern as shown. (The tightened U-Bolt.

Metric Bolt Torque Specifications Chart Porn Sex Picture

7/8" Diameter Round Bend Leaf Spring U Bolts These U-bolt kits can be shipped anywhere in the United States by UPS. Round bend U-bolts that include deep nuts and washers. Click Ubolt part numbers to find out pricing, shipping costs, and to order online. U-bolt Torque Requirements U-bolt Diameter Determination Note - 361-XXX part numbers

Torque Specifications Machine Service, Inc.

The U-bolt grade is a measure of the material's strength. Grades 5 and 8 are the most commonly used with grade 8 material offering an increase in yield strength of over 40% better than that of grade 5 material. This allows for higher torque levels, and thereby, improved spring clamping. Available in 5 / 1. 8 " through 1 / 4 " diameters, grade 8.

Social studies Sea slug Without torque settings for bolts chart Make it heavy fight complexity

US Bolt Torque Chart. Maximum Tightening Torques for US Imperial Bolts.. 7/8: 129: 144: 322: 355: 454: 501: 194: 193: 1: 188: 210: 483: 541: 682: 764: 287: 289: These values should only be used when the machine manufacturer has not provided their own. Metric bolt torque chart. Let us ease your workload! Order metal fabrication from Fractory.

Get Your UBolt Torque Right EATON Detroit Spring

TORQUE-TENSION REFERENCE GUIDE Printed in U.S.A. • Supply Part Number: 9702365 • AS 06/14 Torque Poster. 7/8 14 32479 284 355 403 474 45853 401 502 568 669 53743 470 588 666 784. 8 & 9 BOLTS Locknut Size Threads per inch Steel Hex Locknut Steel Hex Flange Nut Grade C FNL Grade 9 Grade F Grade G

Ball joint torque specs for 72 dart? For A Bodies Only Mopar Forum

Recommended torque levels from the vehicle or suspension manufacturer should always be used where possible. If these specifications are unknown, the following chart can be used as a guide at your own risk. Grade 5. 3/8 (24 threads per inch, SAE) - 30 ft⋅lbf max. 7/16 (20 threads per inch, SAE) - 45 ft⋅lbf max.

Torque guidline for hilti anchors loxapremier

U-bolt Torque Requirements U-bolt Diameter Determination Note - 361-XXX part numbers are U-bolt Kits. 7/8 Diameter Square Bend U-Bolts These U-bolt kits can be shipped anywhere in the United States by UPS. Square bend U-bolts that include deep nuts and washers. Click Ubolt part numbers to find out pricing, shipping costs, and to order online.

Repair Guides Fasteners, Measurements And Conversions Torque

Semi-Round Bend. Square Bend. Forged Top. Semi-Round Bend. Technical Infomation: U-Bolt Grades. The U-bolt grade is a measure of the material's strength. Grade 5 and 8 are the most commonly used with grade 8 material offering an increase in yield strength of over 40% better than that of grade 5 material. This allows for higher torque levels.

Printable Bolt Torque Chart

suggested torque specifications based on u-bolt size, t 2 h 2g7 403-258-7800 403-258-7882 counter standens.com refer to vehicle manufacture's torque specification for exact torque. u-bolts after boo-1 000kms after installed. material size 1/2 9/16 5/8 3/4 7/8 1 1/8 specifications 90 ft/lbs 130 ibo 315 500 750 950 ft/lbs ft/lbs

Gallery Of Tightening Torque Astm F Torque Chart A Bolt Astm 42240 Hot Sex Picture

Get Your U-Bolt Torque Right. Torque is more than the force required to open a beer bottle. The proper torque will keep your leaf spring from breaking. Use your manufacturer's torque specs when tightening your U-bolts, or use our recommendations. U-bolts provide the clamping force required to hold leaf springs to the axle and the right torque.

UBOLTS UTILITY TRAILER

Getting to and from the airport. Budapest's airport shuttle bus - 100E Airport Express - connects the city center (Deák Ferenc tér) with the Ferenc Liszt International Airport. The trip takes about half an hour, and with a €5.5 (HUF2,200) one-way ticket, it's a cheap and quick way to get into and out of the airport.

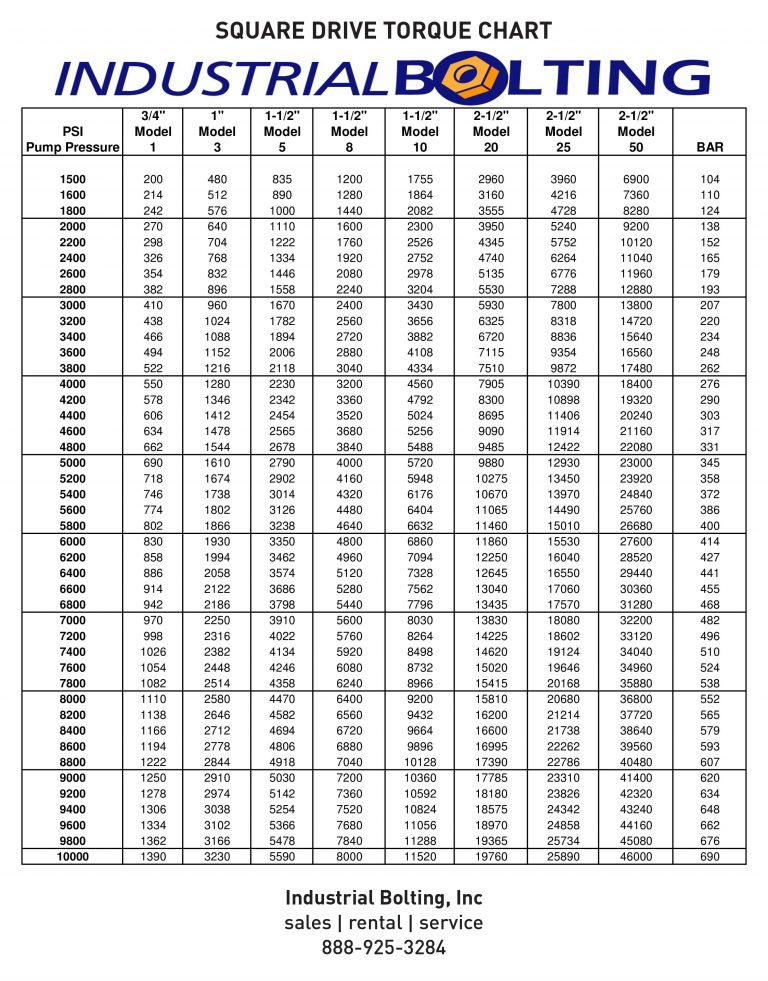

Torque Charts Industrial Torque Tools

If you have any questions or comments, please feel free to call us at 1-877-448-2448 or e-mail us for specific size requirements. Need a quick reference for determining the torque specs of plated and unplated U-bolts in various sizes? Checkout our torque chart for cold-formed U-Bolts.

UBolts Standard

7/8 14 32479 308 355 474 45853 435 502 669 53743 509. The torque values can only be achieved if nut or tapped hole has a proof load greater than or equal to the bolt's minimum tensile strength. 2) ™For A307A, J429 Grade 5 and 8, H-K Grade 9, EcoGuard , A574, A193 B7, Class 4.6, 8.8, 10.9, and 12.9 externally thread fasteners and the.

3rd Gen DIY maintenance quick reference Page 21 World

2. Check the U-bolt torque. See Table 6 for U-bolt torque specifications. Tighten in a diagonal pattern as shown in Fig. 3 . Set a click-type torque wrench to the mid-point torque value for the fastener being checked. Turn the wrench in a clockwise motion (looking up) until the torque wrench clicks, then release pressure on the torque wrench.

- Homes For Sale In Glamorgan Calgary

- Condo A Louer 4 1 2 Laval

- 7 New Bungalow For Sale

- Ultra Paws Durable Dog Boots

- How To Apply For Reconsideration Ircc

- Justice Society Of America 8

- Places For Rent In Strathmore Alberta

- Hayward Pool Heater Control Panel

- Love Story Taylor Swift Piano Sheet Music

- Recipe For Cracker Barrel Coleslaw